Laboratories / Université Laval

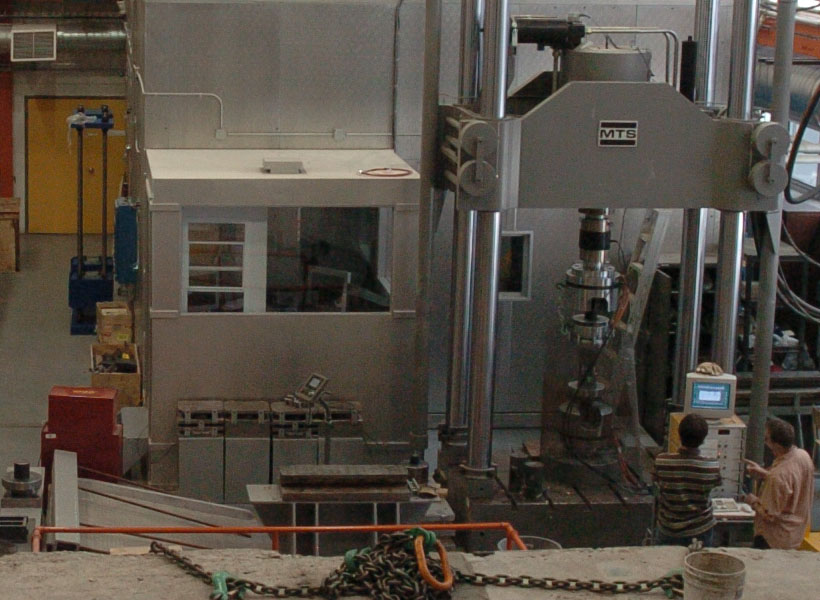

Infrastructure service life research laboratory

This laboratory offers one-of-a-kind equipment used to simulate the severe exposure conditions to which our concrete infrastructure is exposed. Built to accommodate large concrete samples (4 m), the various environmental chambers make it possible to apply freeze-thaw cycles, to reproduce the best conditions for corrosion using a saline mist and to conduct fatigue testing at extreme temperatures.

Contact

- M. Mathieu Thomassin-Mailhot, Eng., M.Sc.A., Research Professional, 1-418-656-2131 # 408733

Shotcrete characterization laboratory

This laboratory entirely equipped for shotcrete production using full-sized equipment is unique in the world, as it enables to carry out research and development activities on shotcrete under controlled conditions. This one-of-a-kind laboratory is the basis for fundamental research in the field of shotcrete, as well as being closely associated with recent developments related to shotcrete equipment and mix design.

Contact

- M. Mathieu Thomassin-Mailhot, Eng., M.Sc.A., Research Professional, 1-418-656-2131 # 408733

Sustainable development of public infrastructure laboratory

This laboratory brings together the vital forces of the entire field of civil engineering. Its water treatment plant, geotechnical test trailer for concrete pavement testing, large structure hall or other available tools enable the conduct of full-size studies on elements found in our public structures. This laboratory also includes equipment for the characterization of cementitious pastes by nanoindentation.

Contact

- M. Mathieu Thomassin-Mailhot, Eng., M.Sc.A., Research Professional, 1-418-656-2131 # 408733

Microanalysis laboratory

The microanalysis laboratory offers the scientific community, businesses and the industry a natural and synthetic materials characterization service. The lab operates a CAMECA SX-100 electron microprobe and a JEOL 840-A scanning electronic microscope (SEM). The laboratory also operates a Siemens D5000 X-ray diffractometer. It is associated with the Geology and Geological Engineering departments, as well as the Mining, Metallurgy and Materials Engineering department.

Contact

- M. Guillaume Barré, Ph.D., Responsable du Laboratoire, 1-418-520-6868